07743989565

01482 420491

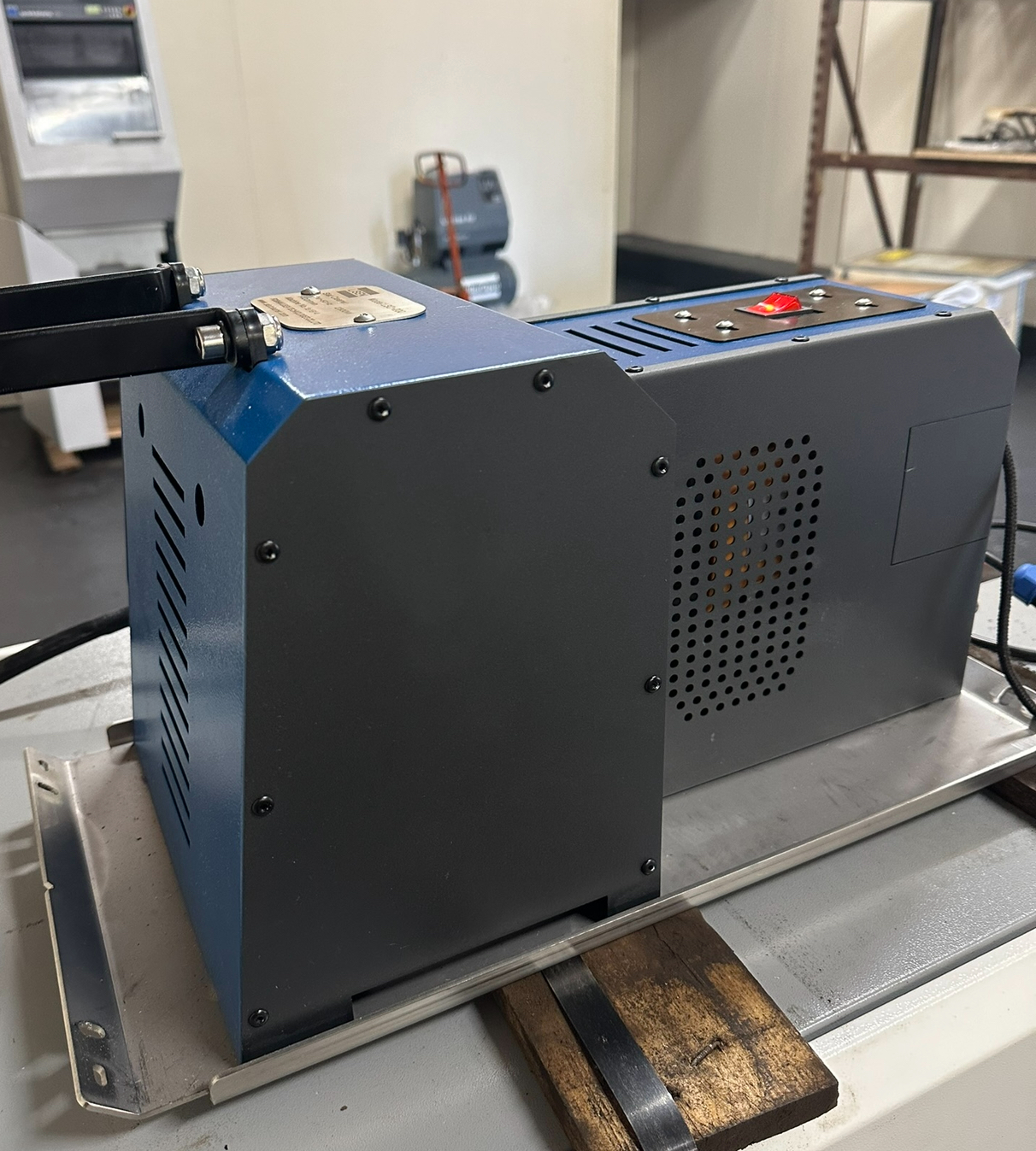

Laser Slat Cleaners

Treat your laser bed to a spa day - keeping the slats slag free is a essential cost effective way of reducing part scratching and keeping extraction flowing

DON'T BE CONFUSED OR BLINKERED IN THINKING THESE ARE THE SAME AS OTHER MODELS ON THE MARKET, THESE ARE NOT REBRANDED AND ARE DESIGNED AND MANUFACTURED AFTER CAREFUL STUDIES - OUT PERFORMING OTHER MANUFACTURERS WITH OUR ROBUST DESIGN AND HEAVY DUTY MOTOR - HARDENED STEEL TEETH - PRECISION GEAR BOX

BUILT TO LAST !!!!!

UK Stock 240v / 415v 2 models depending on kw of laser power

Our Slat Cleaner is engineered to withstand harsh operating conditions, including high temperatures, abrasive materials, and heavy usage. It utilizes durable materials and robust construction techniques to ensure longevity and reliability in demanding industrial environments.

Adopting a modular design, when a failure occurs in one place, the functions of other modules will not be affected. Easy to repair and maintain. The patented gearbox powerful gear traditional system design, all transmission gears and other components undergo a special heat treatment process to achieve optimal wear resistance, fully ensuring the service life of the machine. The gearbox

transmission lubrication part uses high-quality aluminum-based grease that can withstand high temperatures of 300 degrees Celsius to minimize wear of machine parts

Rhino Parter Hammer

The Rhino hammer makes removing tabbed laser cut parts much easier & more quick after they are cut. Reduces Time and Effort Necessary to remove parts from a Nest of Cut Parts. Automatic impact vibration breaks the tab loose with normal pressed shop air. Unique Rhino hammer tips don't mar parts and keep the cut parts in good condition. You will find the Rhino Hammer is one excellent combo of power & ergonomic features. Different Rhino hammer tips for options. This Rhino Hammer is with Steel hammer tips.

Features and specifications of Rhino Hammer:

Works on all different material and thickness

Works for laser or plasma cut parts

Based on the strict industrial standard to prolong the Rhino hammer lifespan.

Part Description: Rhino Hammer, Air Pneumatic hammer, Automatic vibration hammer

Item Weight: 1.3 KG ( 2.6 Pounds)

Package dimensions: 6.5 x 5.47 x 2.76 inches

Material: Metal

Power Source: Pneumatic

Working air pressure: 25 - 125 psi

Stroke per minute: 1,000

Packing List : Rhino Hammer *1, Steel Hammer Tip *1 , Plug *1 , Wrench *2 , Manual*1

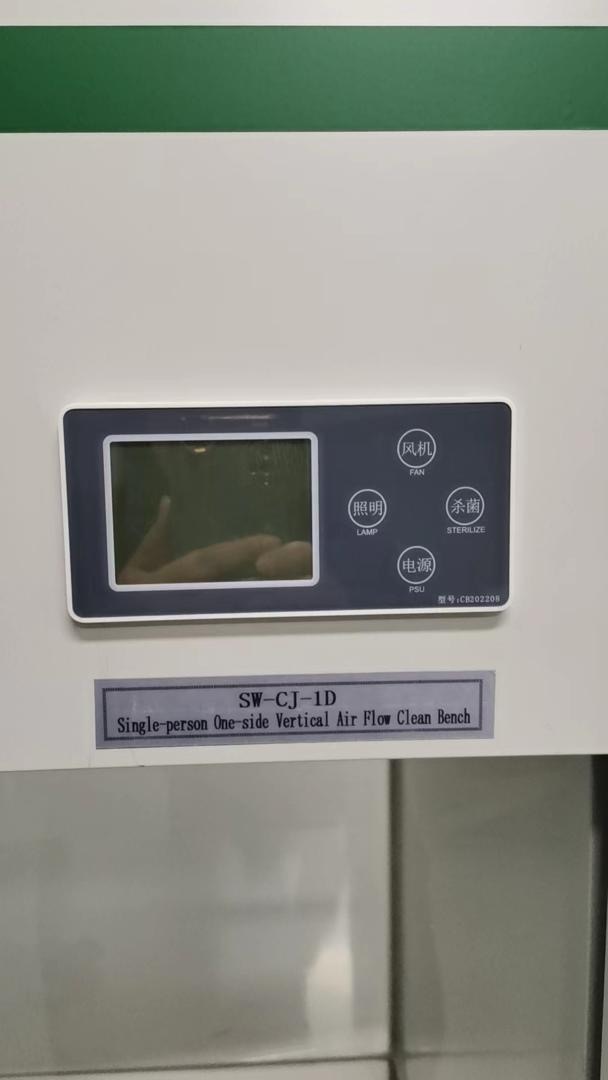

Clean room

Essential For when changing lenses in your laser cut or weld head

Micro Particles are present in the atmosphere and damage the laser lenses when changed if not completed in a clean ( medical ) environment

Common Errors by laser cutting companies is changing lenses at the machine and opening risks to contamination leading to ultimately COSTLY Laser Head DAMAGE

Our clean rooms are manufactured to allow you to change lenses and perform head maintenance.

Coupled with Hepa Filter and Vacuum Environment our Clean Rooms are designed specifically for performing essential Maintenance on your Cutting and Welding Heads .

Single or Double Sided

Contact for More Details